Provides long lasting and reliable operations with our pump tanks and pump skids offering standard and premium features such as full welded stainless steel tanks remote access and monitoring and variable frequency drives.

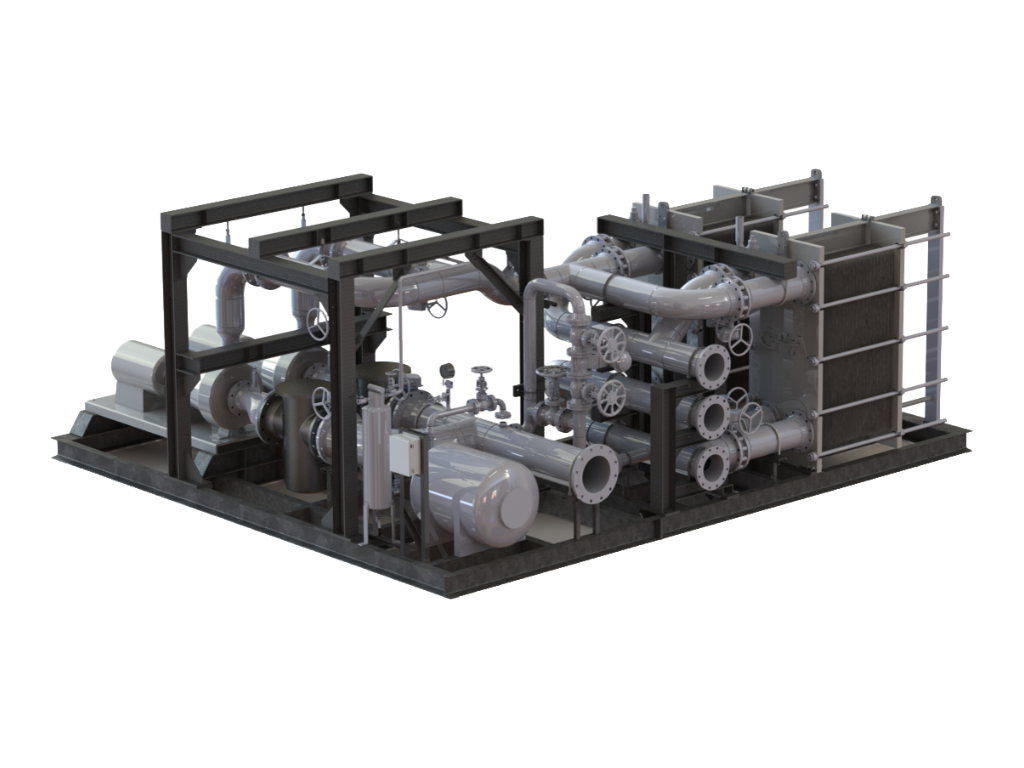

Process cooling water skid.

Process cooling systems inc.

Founded in 1963 process cooling systems inc.

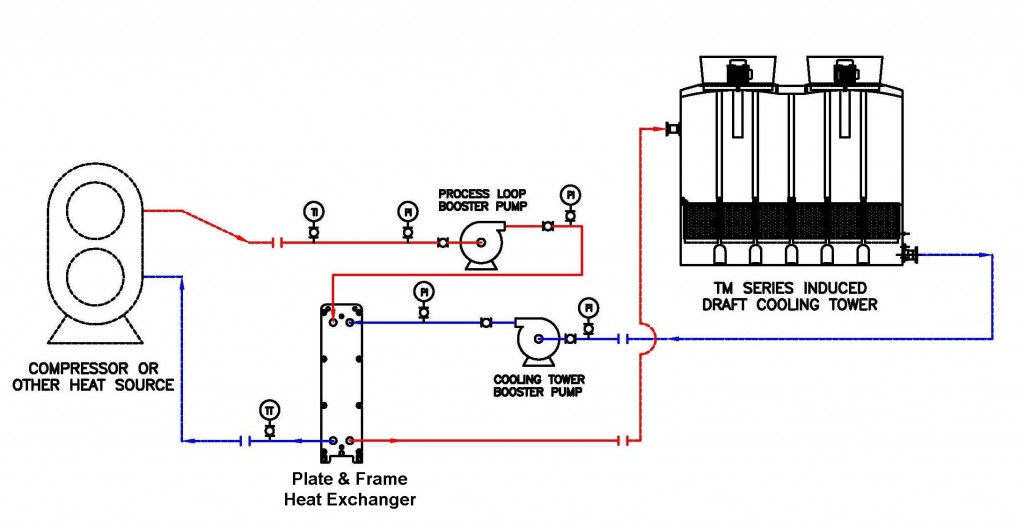

They were designed to re use spent cooling tower water which would then run through one side of a standard xchange heat exchanger and then cool a glycol mixture on the other side of the standard xchange heat exchanger.

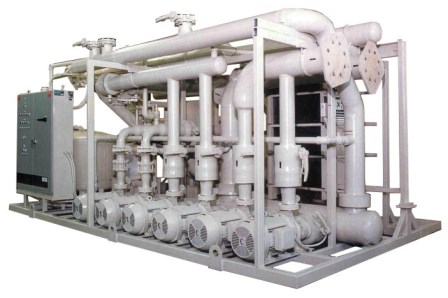

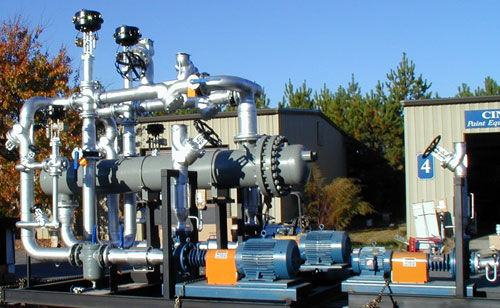

Process water systems are skid mounted pumps that are used to circulate cooling water at a set temperature and pressure.

The control panel includes plc monitoring with flow temperature and pressure.

Process cooling water systems.

The cooled glycol mixture is then sent through.

The cooling skid is designed to include all the required process instrumentation to monitor and maintain the temperature ranges and water coolant quality standards.

Fluid enters the skid and runs through redundant vfd controlled pumps.

When needed most skids have redundant pumps especially in a very critical process that cannot be stopped for a cooling system failure.

Improving cooling system reliability with filtration cooling water corrosion control choosing a water filtration system new products and much more.

Booster skid systems are used to help companies solve process.

Process cooling water systems.

This enables water cooled manufacturing machines to operate more efficiently and stable during manufacturing.

Heating cooling skids.

Description the skid is designed for transferring filtering and cooling of process reverse osmosis water.

Process chilled water systems pcw are compact skid mounted systems that circulate process water at a consistent temperature and pressure to the application s point of use and back allowing for more efficient and stable use of water cooled machines equipment and instruments.

Check out the september 15 2020 edition of process cooling.

Pcw packages are skid mounted systems that circulate process or cooling water at a specific temperature and pressure.

Many process applications are temperature dependent and require both heating and cooling of product to satisfy the process outcome.

Designs installs and services process water systems for industrial manufacturing operations of all types and sizes.

Esi technologies can provide a single unit solution that provides both heating and cooling functionality within a single skid mounted system.

The liquid is sent through a filter chamber and heat exchanger prior to distribution.

With a consistently innovative approach emphasizing energy efficiency performance and reliability process cooling has become the industry leader in providing turkey solutions.